In 27 years of toy export experience, I’ve seen many global buyers fall into the same trap: a Chinese toy supplier’s factory looks perfect during inspection, yet production problems appear once the order begins.

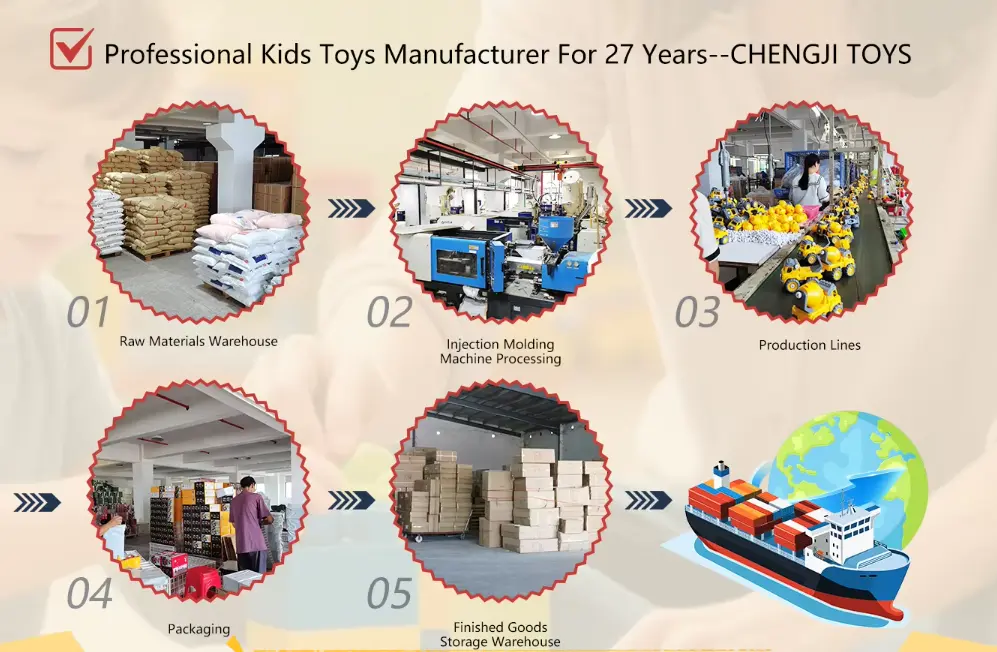

This usually happens because of “ghost factories” (factories that exist only on paper) or “showpiece workshops” (temporary, staged setups). To help importers identify genuine, compliant manufacturers—especially when on-site audits aren’t possible. Chengji, a top toy supplier from China, is bringing to you three practical stages for conducting effective toy factory audits.

Stage 1: Before the Audit – Build a Real Factory Profile, Not a Paper One

The key to a successful toy factory audit is verifying a factory’s existence and legitimacy through double validation.

1. Request official documents with traceability

Ask the supplier to provide a watermarked business license and related operational files. Then, verify the company’s registration through China’s National Enterprise Credit Information Publicity System to confirm it’s not listed as “abnormal operation.”

2. Demand visual proof with time markers

Ask for a panoramic video of the factory gate and workshop that includes today’s newspaper or a digital clock. This prevents them from using pre-recorded stock footage.

Stage 2: During the Audit – Expose “Showpiece” Factories Through Details

In toy manufacturing, three key checks can quickly reveal whether a factory setup is authentic or staged:

1. Equipment and Production Records

Request the factory’s machine ledger and match serial numbers with actual equipment. “Showpiece” factories often rent machines without records or ID numbers.

2. Raw Material Warehouse

Inspect batch labels on toy materials such as fabrics and plastic pellets. They should match purchase order dates—fake setups usually show inconsistent or missing labels.

3. Talk to Frontline Workers

Randomly ask workers simple, practical questions such as:

- “What’s the standard for installing toy safety eyes?”

- “How is fabric tested for quality?”

- “What happens to defective parts?”

If the answers are vague, you’re likely looking at a temporary workforce hired for the toy factory audit.

Stage 3: After the Audit – Ensure Corrective Actions Are Implemented

A real toy factory audit doesn’t end with a site visit—it ends when problems are verified as corrected.

1. Issue a clear audit report with evidence

Summarize each issue by severity:

- Major Defects: Missing toy safety testing equipment

- Minor Defects: Incomplete records or training gaps

- Attach photos for every item as proof.

2. Set measurable follow-ups

Establish a 30–60 day corrective timeline and conduct a video re-audit rather than accepting written claims from the supplier.

Final Thoughts

An effective toy factory audit is more than a compliance task—it’s the first safety barrier in global toy export.

At Chengjitoy, we’ve conducted hundreds of toy factory assessments for international clients, helping them verify authenticity, reduce supply chain risks, and ensure consistent quality. Whether you need a custom supplier-audit checklist or advice on specific toy-category inspection criteria, our professional sourcing team is ready to provide one-on-one support.

Moreover, we have the capability to offer you custom toy solutions as well.

📞Contact us: chengjitoy.com | [email protected] | +86-13715966567