In global toy sourcing, many wholesalers still make the same mistake: choosing toy suppliers purely based on price. But in reality, the biggest losses in the toy business do not come from high unit costs — they come from:

- Unexpected stockouts,

- Failed quality inspections,

- Customs clearance delays.

According to industry feedback, over 40% of wholesalers experience shipment loss or port fines because their suppliers fail to provide timely stock warnings, compliant test reports, or proper customs documents.

For wholesalers, these issues directly damage cash flow, delivery performance, and customer relationships.

This is why choosing a reliable toy supplier is no longer about “who is the cheapest,” but “who can solve problems before they hurt your business.”

Below is how Chengji addresses the three core risks that determine whether your sourcing is profitable — or painful.

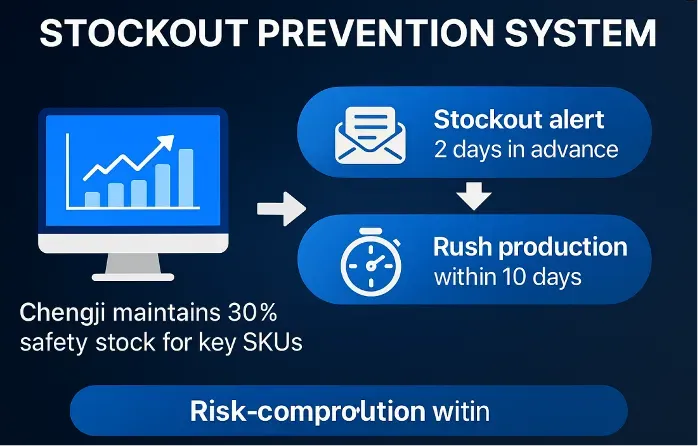

The Stockout Problem: Stable Supply Is More Valuable Than Low Prices

A low price becomes meaningless if the factory cannot keep up with your demand.

How Chengji Helps:

✔ 30% reserve inventory prepared for high-rotation SKUs

✔ Auto stockout alerts 2 days in advance

✔ 10-day rush production for urgent orders (industry average: 15–20 days)

✔ Priority line scheduling for long-term partners

This system ensures that buyers never miss sales peaks, especially during major seasons like Q4, back-to-school, or summer outdoor campaigns.

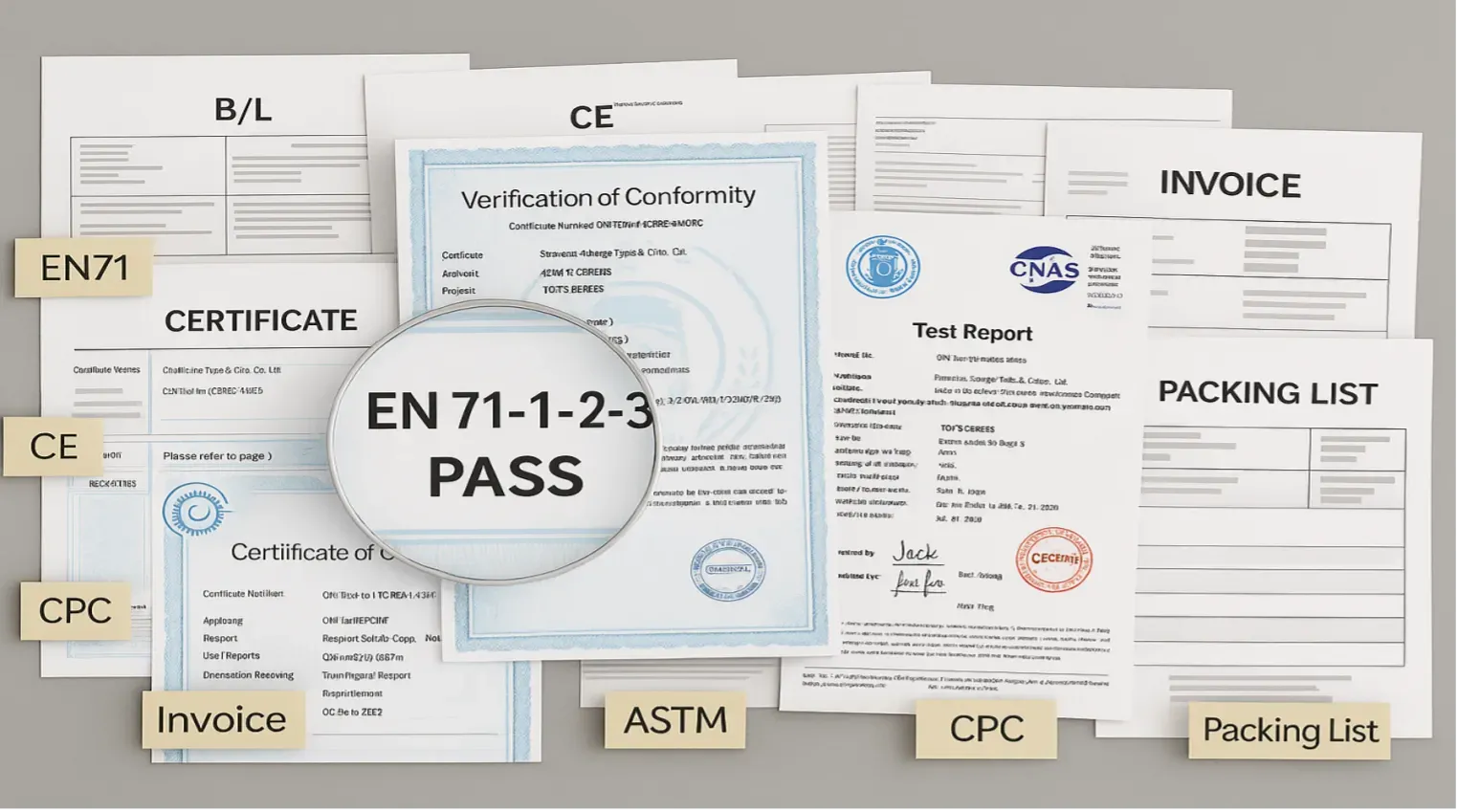

The Quality Problem: Compliance Is the First Line of Risk Control

Many wholesalers struggle with suppliers whose products fail EN71 / ASTM tests or skip internal inspections.

One batch of failed goods can cause:

- marketplace takedowns

- order cancellations

- brand reputation loss

- additional re-inspection or destruction fees

Als Top-Spielzeuglieferant, This is how Chengji helps:

✔ Every shipment includes EN 71 + ASTM dual-certification test reports

✔ Optional CPC / CPSIA / GCC reports for destination markets

✔ 100% full inspection + defect screening

✔ 24-hour quality response

This reduces buyer risk and prevents after-sales disputes.

The Customs Clearance Problem: Missing Documents = Delayed Cash Flow

Poor document handling is one of the most underestimated risks.

Many suppliers provide incomplete or incorrect paperwork, causing:

- port retention

- customs penalties

- delayed delivery

- increased demurrage charges

How Chengji Helps:

✔ “Document Package Service” including:

- Commercial invoice

- Packing list

- Bill of lading

- Certificate of origin

- EN71 + ASTM test reports

✔ Country-specific adjustments (CE for EU / GCC for Middle East / UKCA for UK)

✔ Dedicated bilingual account manager

This ensures zero detention, smooth customs clearance, and faster logistics turnover.

Final Takeaway: Good Toy Suppliers Don’t Just Sell — They Solve Problems

If your sourcing decision is still focused on “who is cheaper?”

You are missing out on the deeper value that determines whether your business grows or bleeds:

- Can they prevent stockouts?

- Can they guarantee quality compliance?

- Can they ensure smooth customs clearance?

The smartest wholesalers now prioritize reliability, transparency, and certification over the lowest unit price.

And this is exactly what Chengji delivers.

Want to See How Chengji Works Behind the Scenes?

📧 E-Mail: [email protected]

📞 WhatsApp / WeChat: +86-13715966567

🌐 Website: www.chengjitoy.com