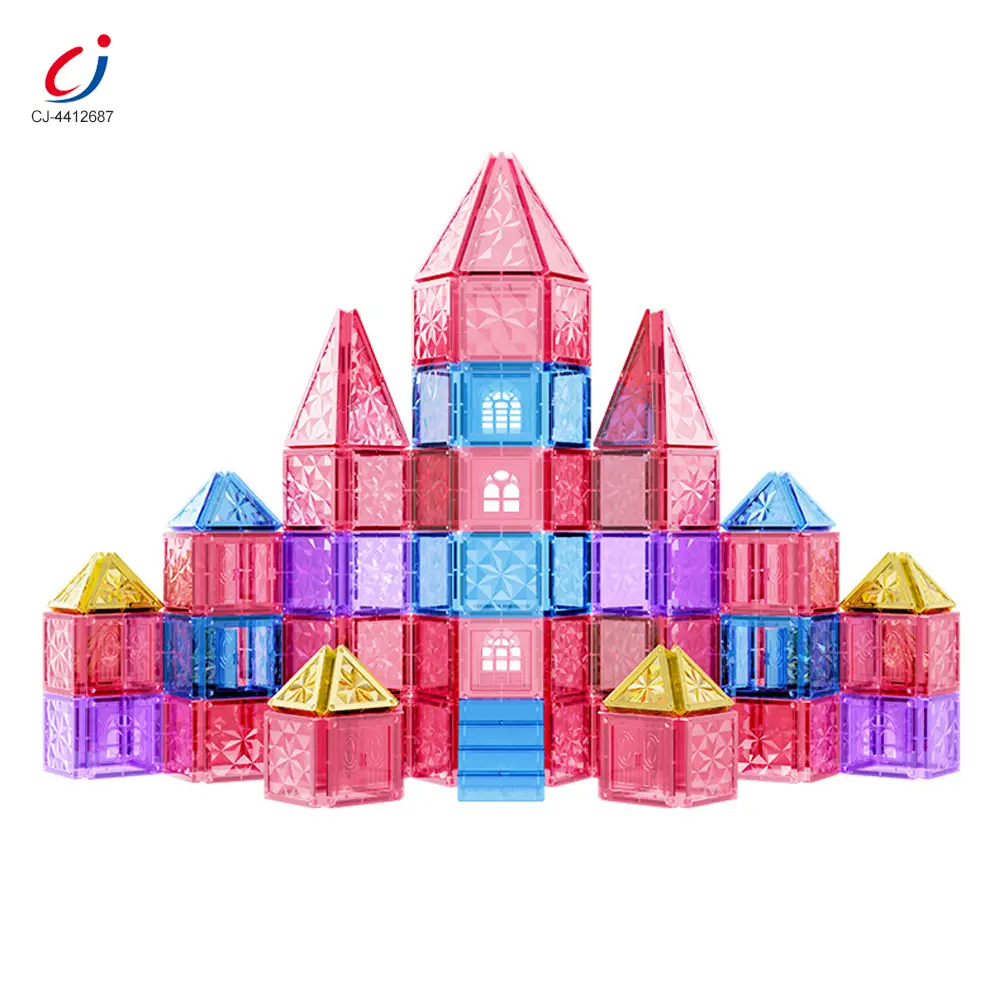

How to Cut After-Sales Complaints by 80% and Avoid Dead Stock

Magnetic building blocks look like a “safe” category. In reality, they are one of the highest-risk SKUs for wholesalers.

I have seen too many buyers make the same mistake: they treat magnetic toys like ordinary plastic blocks.

The result is always the same — high return rates, customer complaints, customs delays, and inventory that doesn’t move.

From my experience working with global wholesalers and importers, over 70% of magnetic building block sourcing problems come from incorrect selection criteria, not from bad luck.

If you choose the wrong product once, the cost does not stop at refunds. It spreads to reputation damage, platform penalties, and frozen cash flow.

That’s why I always recommend starting with three hard, measurable standards. If a magnetic building block fails any one of them, I walk away — no matter how attractive the price looks.

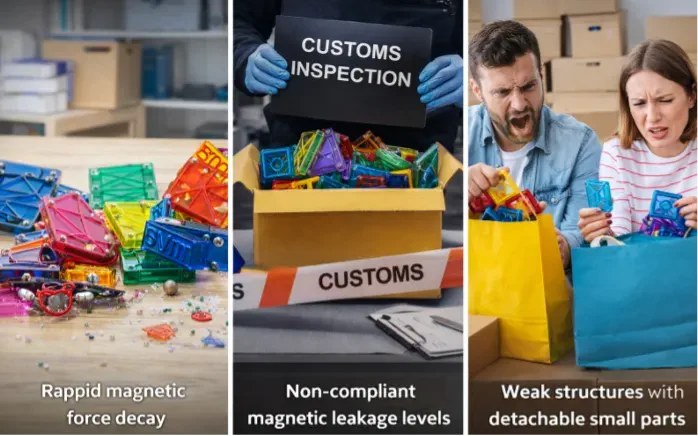

Why Most Wholesalers Lose Money on Magnetic Building Blocks

Many buyers unknowingly select products with:

- Rapid magnetic force decay

- Non-compliant magnetic leakage levels

- Weak structures with detachable small parts

These issues lead to after-sales costs exceeding 15% of total order value, not to mention the risk of shipments being held at customs.

Once goods are stuck at port or rejected by inspection, “cheap” inventory quickly turns into dead stock.

The solution is not experience or intuition. The solution is clear selection standards.

The 3 Non-Negotiable Standards for Choosing Magnetic Building Blocks

Standard 1: Magnetic Force ≥ 8N (No Decay Within 6 Months)

Magnetic strength directly determines customer satisfaction.

When blocks lose attraction after a few months, children can’t build stable structures.

Parents complain. Returns follow.

I use 8N pulling force as my baseline because:

- Structures stay stable during play

- Magnetic force remains consistent over time

- The risk of “can’t stick anymore” complaints drops sharply

Chengji magnetic building blocks use embedded strong magnets and come with third-party pulling force test reports, ensuring stable performance instead of short-term attraction.

This single standard alone prevents a large percentage of early returns.

Example reference:

→ View a magnetic building block set tested at ≥8N pulling force

Standard 2: Dual Certification + Magnetic Leakage Compliance

(EN71 / ASTM + CPSIA)

Magnetic toys sit under strict regulatory supervision.

If magnetic leakage exceeds limits, customs may classify the product as unsafe — even if it sells well in your domestic market.

That’s why I only recommend products that provide:

- EN71 compliance for Europe

- ASTM + CPSIA compliance for the U.S.

- Batch-specific magnetic leakage test reports

Chengji supplies full certification with every shipment, eliminating the risk of document gaps, delayed clearance, or forced destruction.

For wholesalers, compliance is not paperwork — it is risk insurance.

Standard 3: Safe Materials + Reinforced Structure

(Food-Grade ABS, Zero Detachable Small Parts)

Most after-sales complaints do not come from magnets.

They come from structural failure.

I always check three details:

- Food-grade ABS material with no chemical odor

- Fully rounded edges with proper polishing

- Passed 1.5-meter drop tests without cracking or separation

When blocks break, edges cut skin, or internal parts loosen, complaints escalate fast — especially in EU and North American markets.

Chengji magnetic building blocks use reinforced structures and strict internal QC, keeping after-sales complaint rates below 2% in real shipments.

How Chengji Helps Wholesalers Apply These Standards with Low Risk

Knowing the standards is one thing. Applying them without increasing financial pressure is another.

This is where Chengji’s supply model makes the difference.

- Chengji allows wholesalers to start with just 2 cartons, making it possible to test the market through sample-based trial sales before committing to larger volumes. This approach significantly reduces trial-and-error costs and helps avoid dead stock.

- At the same time, Chengji maintains stable and fast production schedules — 15 days for regular orders 和 10 days for urgent replenishment — ensuring buyers don’t miss peak sales windows or face emergency stockouts.

- To support independent decision-making, Chengji also provides a free Product Verification Toolkit, including magnetic force testing methods, certification checks, packaging warning guidelines, and key pre-shipment inspection points.

I believe wholesalers should verify, not blindly trust — and this model makes that possible.

Final Thought: In 2026, Low Risk Beats Low Price

Magnetic building blocks remain a high-potential category.

But profit does not come from chasing the lowest unit cost.

It comes from:

- Stable quality

- Compliance certainty

- Low after-sales pressure

- Flexible supply

If you follow these three hard standards, you will avoid 80% of common sourcing pitfalls and keep your inventory moving.

If you plan to add or expand magnetic building blocks in your 2026 lineup, I strongly recommend starting small, verifying performance, and scaling with confidence.

If you want the 2026 magnetic building block catalog, test reports, and pricing, feel free to contact me directly.

I’m happy to help you reduce risk before you place your next order.